A Metallurgical Microscope Part 1

What is a metallurgical microscope?

Metallurgical microscope is basically a microscope that shines light from the top. Wait, I hear you say, my normal microscope shines light from the top. You see, the difference is that the ordinary microscope shines light from about the top whereas metallurgical one shines it exactly from top, using same optical path for lighting and looking. A diagram will explain it better.

|

| metallurgical microscope's optical path |

|

| standard microscope's optical path |

Why would anyone want that?

In order to find an answer to this interesting question, we should ask ourselves why

anyone wouldn’t want that. In microscopy just like in a real life, we rely on the shadows to sense depth. With a simple flashlight we can check that source of light near eye eliminates shadows and makes depth sensing harder, if not impossible.

We know what we're losing but what are we gaining? As it turns out few things:

- Many surfaces, especially metallic ones change reflectivity a lot with just small angle variations. By that, we can see small imperfections in a surface finish. (this is where name comes from)

- All surfaces reflect light. The more perpendicular we are the less light gets reflected (see Fresnel equation). That allows us to look at dark targets under some transparent medium (water, other solvents, glass, etc) without a problematic reflection on the fluid surface

- And finally, the one I'm interested in looking at semiconductors. It turns out that this type of microscopy allows to see doping in silicon. I'm not really sure how it works, but if I were to guess, I'd say it's because of 2 reflections under and over doped area and created interference.

Building a DIY version

As you might have figured out I don't like writing pure, theoretical posts. Each posts means I did something I want to share, and this time is no different. The obviously tricky part is cyan thing that magically bends one beam and not the other. For that task I decided to use 50/50 beam splitter I bought a while ago. I designed new top part for my scope, 3d printed, put everything together and it didn't work.

| model of a new top part |

Image had poor contrast and seemed to have 2nd ghost element I couldn't focus on. Here I have to confess to a small lie. Beam splitter doesn't magically bend light coming in. As a name suggest it simply splits light beam in two equal parts bending one and keeping other intact. So in reality there's second light path "imaging" back side of my adapter.

|

| second optical path and lenses. |

The lens at the top explains why image was out of focus and why microscope's focus control didn't change that.

I thought that printing it in black PLA would solve THE issue as THE second beam would get absorbed but it turns out it absorbs around 90% of light hitting it. While it seems like a lot, it means 10% of the light gets reflected back. This is what makes us see the surface finish. I shoulD've thought about it before, now I'm screwed. Or am I not?

musou black

I barely remembered some news article about vanta black. Supposedly world darkest paint. Further research revealed I couldn't really buy it as it requires high temperature carbon nanotube coating which makes it both expensive and destructive to 3d prints. When I was losing hope, I came up to musou black. This is a one Japanese artist creation. Acrylic paint that AFTER DRYING (try don't making my mistake of crying too quickly) absorbs 99.4% of light. Now the reflection dropped from around 10% to 0.6% - over 10 times improvement. Pictures still have a low contrast but at least now I am able to see some things I was interested in.

Photo time

Quality is terrible as photos were taken by bringing phone close to microscope's eyepiece, trying to net shake it out of focus.

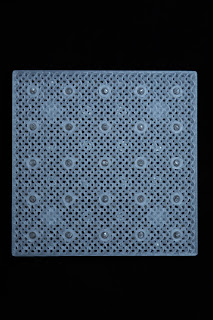

|

| metallurgical photo |

|

| lighting from top in normal mode |

Comments

Post a Comment