dye laser

As I'm a little tired with writing more about soalr project and I'm currently waiting for V2 PCBs to arrive I decided to go back to optics and experiment with it a bit.

|

| Teaser |

After listening to the laser lecture, I realized that all fluorescent substances are either 3 or 4 level systems, so in theory they should be capable of laser action (though most of them have their energy level lifetime's set in a way that makes it very hard to obtain laser action). From available and affordable dyes I found two that interested me the most:

- Rhodamine B

- Chlorophyll

Rhodamine B was used extensively in many dye lasers before. There're many materials available and results are almost guaranteed. On the other hand, chlorophyll doesn't seem to be studied extensively as a laser dye and the only paper I found is the following: https://www.researchgate.net/publication/269952977_A_Possible_Realization_of_Chlorophyll_Lase

Those who know me can guess I chose the harder way.

Chlorophyll problems

Getting the dye itself is not as easy as it seems to be. I thought it's simply a matter of dissolving some green thing in an organic solvent but I was so wrong.

Simple wiki search shows that there're multiple types of chlorophyll: a,b, c1, c2, d and f. Fortunately for us, we care only about type a and b as they're most abundant and the easiest to get. They differ in an absorption and an emission spectrum. Things get further complicated because the solvent modifies the spectrum a bit.

|

| source: wikipedia |

What we hope for is for a molecule to absorb blue light, dissipate some energy and simulated emit it in red spectrum. Semiconductor blue laser operates at 405nm, which makes it well suited for pumping chlorophyll a.

Solvents also dissolve other things from plants (that diffuse light beam) and influences quantum yield. Finding info about it is quite hard unfortunately, researchers contributing in the paper used acetone, so we'll stick with it for now too.

chlorophyll dies when pumped

According to the research mentioned above "red fluorescence is most prominent when excited with broad band source like 30 mW green or blue solid state laser". I don't get the broadband laser thing, maybe they meant that there's a big absorption window that can be used. The thing which I missed is, they excited it with a 30mW green laser.

As I wanted to go high power I had to use a blue laser (getting a green laser light is hard and inefficient). After focusing the beam tightly inside the flask and setting the beam power ~1W, I was happy to see a strong red light. Unfortunately, after playing around for a few minutes the intensity decreased and what's more important the beam stopped decreasing in power as it traveled through the flask and more blue light hit detector after. Also the liquid lost most of its green color. This suggests that the dye decomposed, which makes sense if you think about it. Even assuming the quantum yield of 1 (all incoming photons are converted to output photons) by changing 405nm to 662nm we're dissipating 38.8% of the power as a heat. Adding to this dissipation on some contaminants (beam was diffused quite a bit) and a lower quantum yield we can approximate power loss to 50%. And focused beam, delivering 500mW of heat, could easily locally overheat the dye, even with all this acetone around for cooling. Assuming loosely focused beam, we're still talking about few W/mm^3

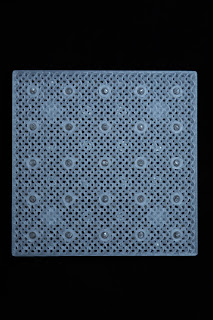

|

| Setup with blue beam removed. Laser diode on right, the dye in flask, a copper used to capture the beam |

You can see how the pump beam gets absorbed by dye (power decreasing from right to left).

Getting rid of an excess laser beam

The thing that I feel needs addressing, is what to do after your experiment. Pumping laser beam doesn't end at the flask, it travels forward, hitting unexpected things, getting absorbed (good), diffused (acceptable) and reflected (very bad). Laser safety says that the beam with power lower than 5mW is safe to work with, so here we need to attenuate it 200 times to get into a safe working range. Just letting it go to hit something is a bad idea, which I found after burning myself. One way to handle it is to de-focus it rapidly with some lenses. This makes the light hitting the wall behave more like LED than laser, it works as long as you can make sure lens-wall path is not obstructed (which can be done reliably only with the ceiling). The proper way is to dissipate it as a heat. There're commercially sold beam traps, containing diffusers and a really black material to capture photons and change them into heat. But for 405nm laser there's a simple trick we can use. Copper has a high absorbance in the blue spectrum and it conducts heat well enough to not melt even with a highly focused beam. And the residual beam gets reflected into the ceiling.

Comments

Post a Comment